Metal fabrication is a vital industry in Saudi Arabia, contributing significantly to the construction, manufacturing, and infrastructure sectors. The kingdom’s rapid development and ambitious projects have created a robust demand for high-quality metal fabrication services.

In this blog article, we will explore various metal fabrication companies operating in Saudi Arabia, highlighting their services, capabilities, and contributions to the industry. One notable company in this sector is Al Auz Contracting Co., which has made significant strides since its establishment.

Understanding Metal Fabrication

Metal fabrication involves the process of constructing machines and structures from raw metal materials. It encompasses a range of processes including cutting, bending, welding, and assembling metal components into finished products. This industry plays a crucial role in various sectors such as construction, automotive, aerospace, and energy.

Key Processes in Metal Fabrication

- Cutting: The process of dividing metal sheets into specific sizes using tools like lasers, plasma cutters, or saws.

- Bending: Involves deforming metal sheets into desired shapes using press brakes or other bending machines.

- Welding: A method of joining metal pieces together by melting them at their edges and allowing them to cool to form a strong bond.

- Assembling: The final stage where fabricated components are put together to create the final product.

Major Metal Fabrication Companies in Saudi Arabia

Saudi Arabia is home to several reputable metal fabrication companies that cater to diverse industrial needs. Below is a list of some prominent players in the market:

- Al Auz Contracting Co.

- AFCO Steel

- Kaisab Company

1. Al Auz Contracting Co.

Al Auz Contracting Co. is a leading player in the metal fabrication industry in Saudi Arabia. Established in 2015, the company has quickly gained recognition for its commitment to quality and innovation.

- Services Offered:

- Metal structuring

- Excavation

- Concrete work

- Brick masonry

- Roof laying

- Flooring

- Key Projects:

Al Auz has successfully completed various complex projects including bridges, luxury villas, hotels, schools, and multi-story developments. Their focus on safety, quality, and efficiency ensures that each project meets the highest standards. - Website: Al Auz

2. AFCO Steel

AFCO Steel has established itself as a premier provider of steel fabrication services in Saudi Arabia since its inception in 2010. The company specializes in designing and erecting steel structures for various industries.

- Services Offered:

- Structural steel fabrication

- Project management

- Custom steel products

- Key Clients:

AFCO Steel has worked with esteemed clients like Saudi Aramco and has a proven track record of delivering high-quality products on time.

3. Kaisab Company

Founded in 2000 and based in Riyadh, Kaisab Company specializes in stainless steel and metal fabrications. The company serves both residential and industrial sectors.

- Services Offered:

- Manufacturing of metal catwalks

- Steel structures and frames

- Steel stairs and ladders

- Technological Edge:

Kaisab is equipped with modern machinery ensuring high-quality production tailored to client specifications.

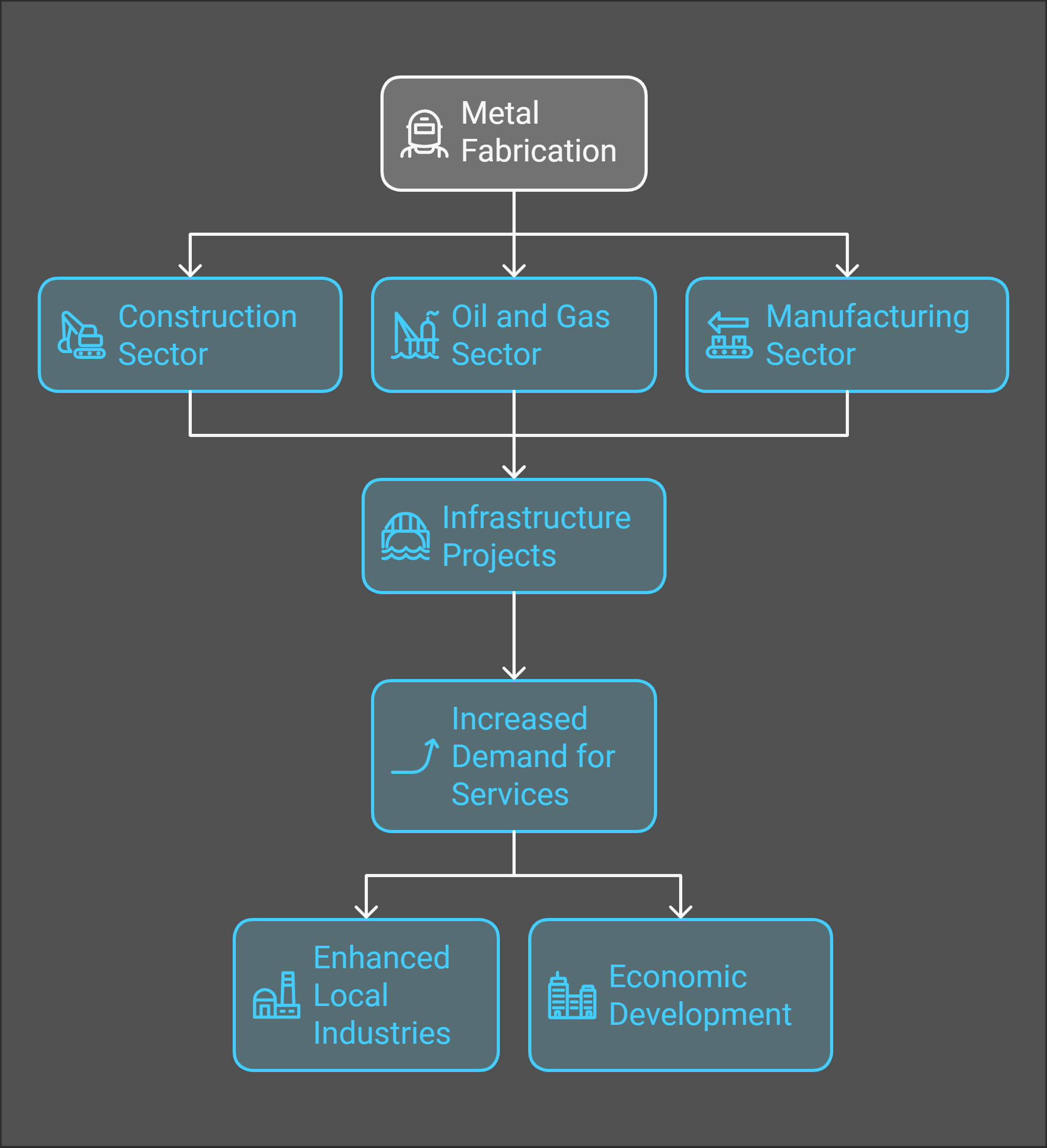

The Importance of Metal Fabrication in Saudi Arabia

The growth of the construction sector in Saudi Arabia has been fueled by large-scale projects such as NEOM and other Vision 2030 initiatives. Metal fabrication companies play a crucial role by providing essential materials and structures needed for these developments.

Economic Impact

The metal fabrication industry contributes significantly to the economy by:

- Supporting local job creation.

- Enhancing the capacity for infrastructure development.

- Promoting technological advancements within the sector.

Trends Shaping Metal Fabrication in Saudi Arabia

Several trends are influencing the future of metal fabrication in Saudi Arabia:

- Technological Advancements: Adoption of automation and advanced manufacturing technologies such as robotics and AI is streamlining production processes.

- Sustainability Practices: Companies are increasingly focusing on environmentally friendly practices by recycling materials and reducing waste during fabrication processes.

- Customization Demand: There is a growing trend towards customized solutions tailored to specific client needs across various industries.

The metal fabrication industry in Saudi Arabia is poised for continued growth driven by ambitious national projects and increasing demand for quality construction materials.

Companies like Al Auz Contracting Co., AFCO Steel, and Kaisab Company are at the forefront of this evolution, providing innovative solutions that meet the complex needs of modern construction.

What are the key factors that make a metal fabrication company successful in Saudi Arabia?

The metal fabrication industry in Saudi Arabia is experiencing significant growth, driven by the country’s ambitious infrastructure projects and economic diversification efforts under Vision 2030.

To thrive in this competitive landscape, metal fabrication companies must navigate a variety of challenges and leverage key success factors. Below we will explore the essential elements that contribute to the success of metal fabrication companies in Saudi Arabia.

1. Investment in Advanced Technology

Technological Advancement

One of the most critical factors for success in metal fabrication is the investment in advanced technologies. Companies that adopt cutting-edge machinery and automation can significantly enhance their production capabilities. The integration of robotics, CNC machines, and advanced welding techniques allows for:

- Increased Efficiency: Automation reduces production times and labor costs while increasing output quality.

- Precision Manufacturing: Advanced technologies ensure high levels of accuracy in cutting, bending, and assembling metal components.

- Adaptability: Companies can quickly adjust to changing market demands by utilizing flexible manufacturing systems.

2. Commitment to Quality Standards

Quality Assurance

Maintaining high-quality standards is essential for building a strong reputation and ensuring customer satisfaction. Successful metal fabrication companies adhere to international quality certifications such as ISO 9001, which helps them:

- Ensure Consistency: Regular quality checks and adherence to standards lead to consistent product quality.

- Build Trust: Clients are more likely to choose companies with a proven track record of delivering reliable products.

- Reduce Waste: High-quality processes minimize defects, leading to reduced material waste and lower costs.

3. Sustainability Practices

Environmental Responsibility

With growing global emphasis on sustainability, metal fabrication companies that adopt environmentally friendly practices can gain a competitive edge. Key sustainable practices include:

- Use of Recycled Materials: Incorporating recycled metals reduces environmental impact and conserves resources.

- Energy Efficiency: Investing in energy-efficient machinery lowers operational costs and aligns with regulatory standards.

- Waste Management Programs: Implementing recycling and waste reduction strategies enhances sustainability efforts.

4. Skilled Workforce Development

Talent Acquisition and Training

A skilled workforce is vital for the success of any manufacturing operation. Companies that prioritize employee training and development can benefit from:

- Enhanced Productivity: Well-trained employees are more efficient and capable of operating complex machinery.

- Innovation: A knowledgeable workforce can contribute ideas for process improvements and new product developments.

- Retention Rates: Investing in employee development fosters loyalty and reduces turnover rates.

5. Strong Supply Chain Management

Efficient Logistics

Effective supply chain management is crucial for ensuring timely access to raw materials and components. Successful companies focus on:

- Local Sourcing: Engaging local suppliers reduces lead times and transportation costs while supporting the local economy.

- Inventory Management: Implementing just-in-time inventory systems minimizes excess stock and associated holding costs.

- Supplier Relationships: Building strong relationships with suppliers ensures reliability and better negotiation terms.

6. Customer-Centric Approach

Understanding Client Needs

A customer-centric approach is essential for long-term success. Companies that focus on understanding their clients’ specific needs can:

- Deliver Customized Solutions: Tailoring products to meet unique client specifications enhances satisfaction.

- Build Long-Term Partnerships: Strong relationships with clients lead to repeat business and referrals.

- Respond to Feedback: Actively seeking customer feedback allows companies to improve their offerings continuously.

7. Government Support and Initiatives

Leveraging National Programs

The Saudi government has implemented various initiatives to support local manufacturing, including the National Industrial Development and Logistics Program (NIDLP) and the “Made in Saudi” program. Successful companies take advantage of these programs by:

- Accessing Financial Incentives: Government grants or subsidies can help offset investment costs in technology or training.

- Participating in Local Manufacturing Initiatives: Engaging with government programs fosters innovation and helps reduce dependency on imports.

The metal fabrication industry in Saudi Arabia presents numerous opportunities for growth, driven by government initiatives and increasing demand from various sectors. By focusing on key factors such as technological investment, quality assurance, sustainability practices, workforce development, supply chain management, customer-centric approaches, and leveraging government support, metal fabrication companies can position themselves for long-term success in this dynamic market.

As the industry continues to evolve, those who adapt to these critical success factors will thrive amidst competition and changing market demands.