The metal fabrication industry in Saudi Arabia is experiencing a transformative phase, driven by rapid technological advancements and government initiatives aimed at economic diversification.

In this blog article, we will explore about the current trends shaping the metal fabrication sector in the Kingdom, highlighting key technologies, challenges, and future outlooks.

Overview of Metal Fabrication in Saudi Arabia

Metal fabrication involves creating metal structures through processes such as cutting, bending, and assembling. This industry is vital for various sectors, including construction, automotive, and manufacturing.

The Kingdom’s Vision 2030 initiative has catalyzed growth in this sector by promoting local manufacturing capabilities and reducing reliance on imports.

Key Drivers of Growth

- Infrastructure Development: Major projects like NEOM and the Riyadh Metro are driving demand for fabricated metal products.

- Economic Diversification: The government’s push towards reducing oil dependency is fostering innovation within the sector.

- Technological Advancements: The integration of automation and digital technologies is enhancing productivity and efficiency.

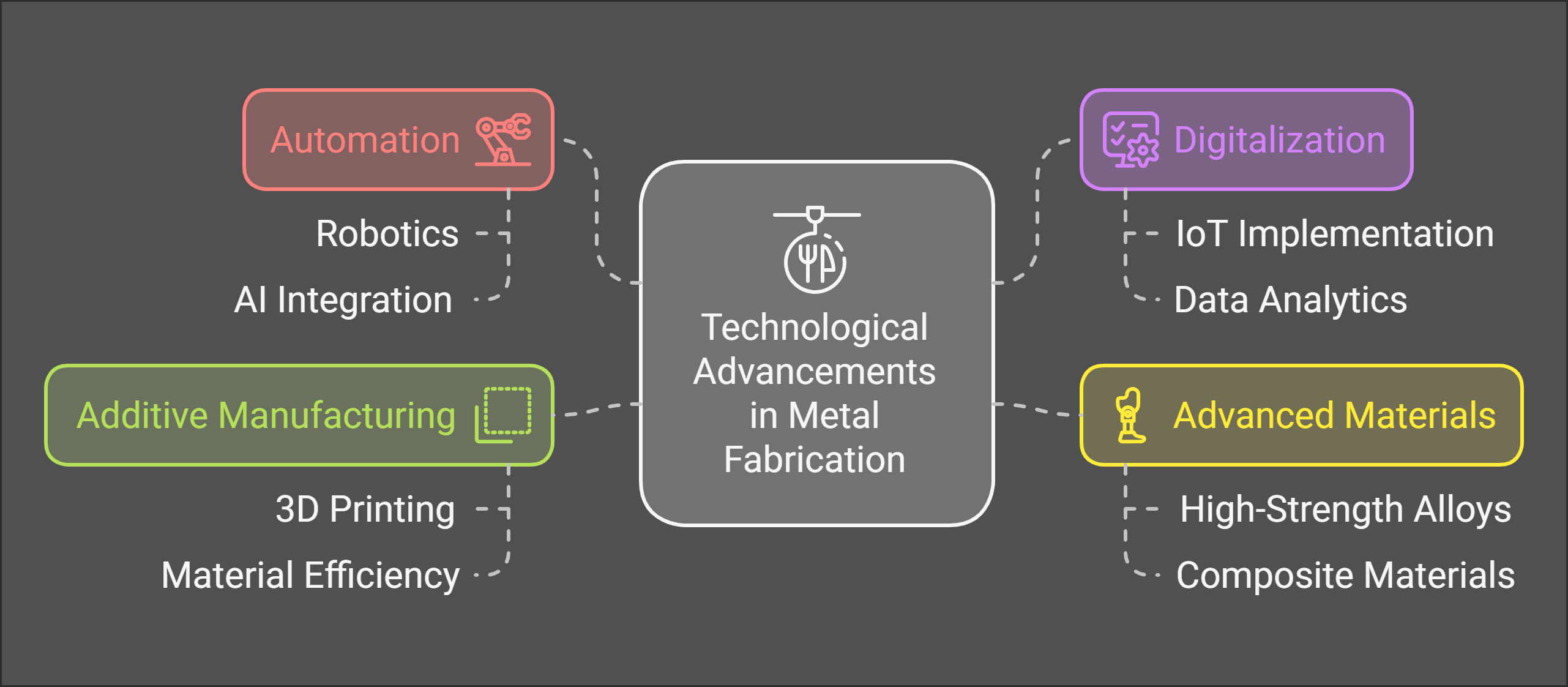

Current Technological Trends

The following technological trends are significantly influencing the metal fabrication industry in Saudi Arabia:

1. Adoption of Industry 4.0

Industry 4.0 refers to the integration of IoT (Internet of Things) devices into manufacturing processes. In Saudi Arabia, this trend includes:

- Real-time Data Analytics: Manufacturers utilize IoT devices for monitoring production efficiency and equipment performance.

- Predictive Maintenance: By leveraging data-driven insights, companies can reduce downtime and extend machinery lifespan.

2. Artificial Intelligence (AI) Integration

AI is playing a crucial role in optimizing operations within the metal fabrication sector:

- Process Optimization: AI applications analyze production data to identify inefficiencies and bottlenecks.

- Informed Decision-Making: Enhanced data analysis capabilities enable manufacturers to make strategic decisions that improve productivity.

3. Automation and Robotics

The deployment of robotics is set to expand significantly in Saudi Arabia:

- Industrial Robots: The Kingdom aims to deploy over 50,000 industrial robots by 2030 to enhance productivity across various sectors.

- Precision Manufacturing: Automation technologies improve accuracy in processes such as welding, cutting, and assembly.

Sustainability Trends

Sustainability is becoming increasingly important within the metal fabrication industry:

- Green Manufacturing Practices: There is a growing demand for environmentally friendly fabrication processes that minimize waste and energy consumption.

- Regulatory Compliance: Companies adopting sustainable practices are better positioned to meet regulatory standards and consumer expectations.

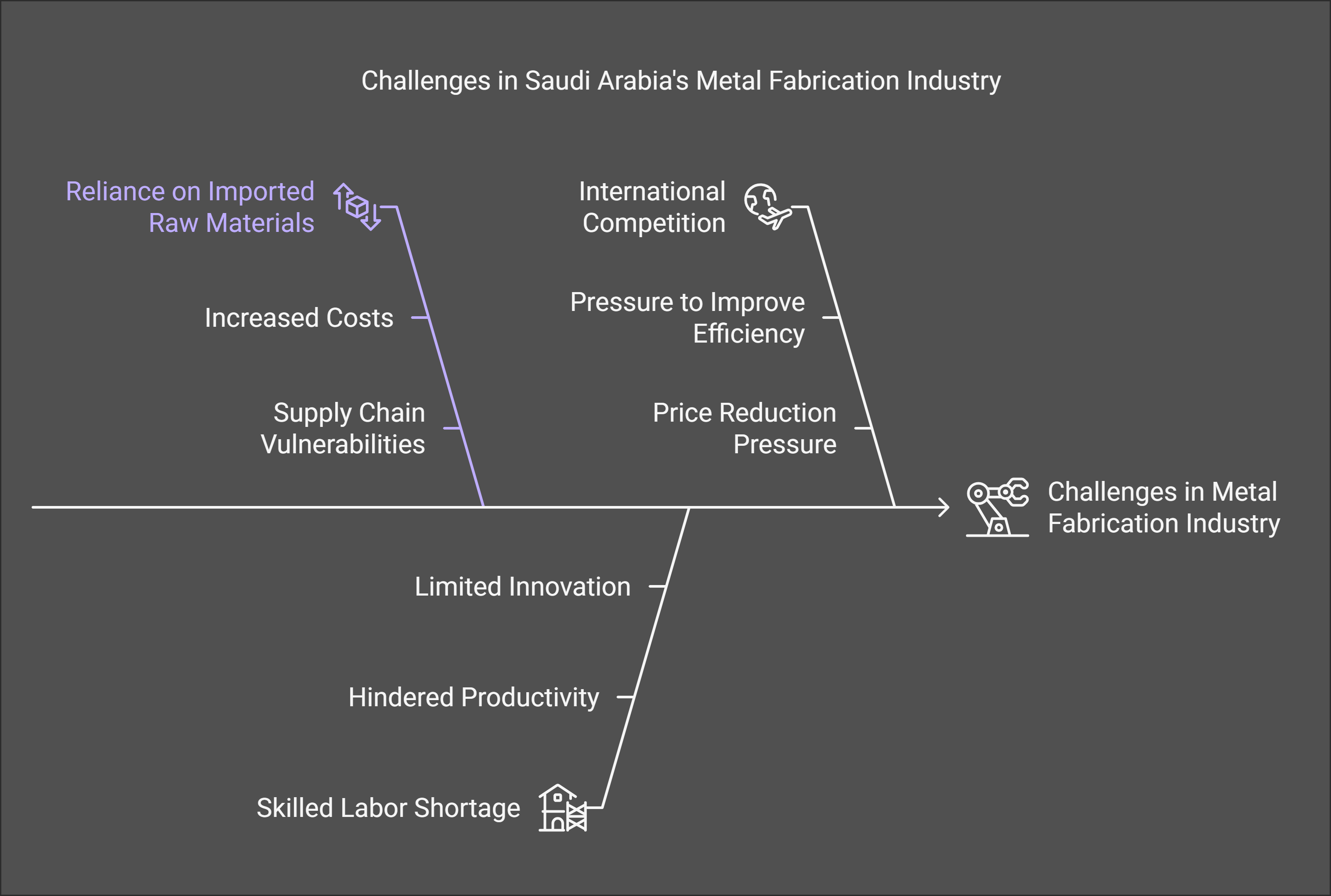

Challenges Facing the Industry

Despite the positive trends, several challenges persist within the metal fabrication sector:

1. Skilled Labor Shortages

The rapid adoption of advanced technologies requires a workforce skilled in operating complex machinery. The current shortage of skilled labor poses a significant challenge for companies looking to innovate.

2. Fluctuating Material Costs

Volatility in raw material prices can impact profitability. Companies must develop strategies to manage these fluctuations effectively.

3. Initial Investment Costs

Investing in advanced technologies can be prohibitively expensive for some businesses. Overcoming this barrier requires careful financial planning and potential government support.

Future Outlook

The future of the metal fabrication industry in Saudi Arabia looks promising, driven by ongoing technological advancements and government initiatives:

- Increased Local Production: The government’s focus on local manufacturing will reduce import dependency and foster innovation.

- Expanded Use of Advanced Technologies: Continued investment in automation, AI, and sustainable practices will enhance competitiveness.

- Growth Opportunities: As infrastructure projects continue to expand, demand for fabricated metal products will rise, creating new business opportunities.

The metal fabrication industry in Saudi Arabia is at a pivotal moment, characterized by rapid technological advancements and significant government support. By embracing automation, AI, and sustainable practices, companies can enhance their operational efficiency while contributing to the Kingdom’s economic diversification goals under Vision 2030.

As challenges such as skilled labor shortages and fluctuating material costs persist, proactive strategies will be essential for navigating this dynamic landscape successfully.

Key Takeaways

| Trend/Challenge | Description |

|---|---|

| Adoption of Industry 4.0 | Integration of IoT devices for real-time monitoring and predictive maintenance |

| AI Integration | Use of AI for process optimization and informed decision-making |

| Automation & Robotics | Expansion of industrial robots to enhance productivity |

| Sustainability | Growing emphasis on environmentally friendly practices |

| Skilled Labor Shortages | Need for a workforce skilled in advanced technologies |

| Fluctuating Material Costs | Impact on profitability due to volatility in raw material prices |

| Initial Investment Costs | Financial barriers to adopting advanced technologies |

What are the most significant technological advancements currently impacting metal fabrication in Saudi Arabia?

The metal fabrication industry in Saudi Arabia is undergoing significant transformation due to various technological advancements. These innovations are enhancing precision, efficiency, and overall productivity in the sector. Here are some of the most significant technological advancements currently impacting metal fabrication in Saudi Arabia:

Key Technological Advancements in Metal Fabrication

1. CNC Machining

Computer Numerical Control (CNC) machining has revolutionized the way metal components are fabricated. This technology automates the control of machine tools through computer programming, allowing for:

- Increased Precision: CNC machines provide high accuracy in cutting, shaping, and drilling metals, significantly reducing human error.

- Faster Production Times: Automation speeds up the manufacturing process, enabling quicker turnaround for projects.

- Reduced Material Waste: Precise cuts minimize excess material usage, leading to cost savings.

2. Laser Cutting Technology

Laser cutting is another critical advancement that has gained traction in the metal fabrication industry:

- High Precision: This method uses a focused laser beam to cut materials with exceptional accuracy, making it suitable for complex designs.

- Clean Cuts: Laser cutting produces smooth edges with minimal need for secondary finishing processes.

- Efficiency: It allows for faster production rates compared to traditional cutting methods, which is essential for meeting high demand.

3. 3D Metal Printing

3D metal printing is emerging as a game-changer in the fabrication landscape:

- Complex Shapes: This technology enables the creation of intricate designs that are difficult or impossible to achieve with traditional methods.

- Material Efficiency: By building objects layer by layer from a digital file, 3D printing reduces waste significantly.

- Customization: It allows for rapid prototyping and tailored solutions for specific client needs.

4. Automation and Robotics

The integration of automation and robotics is transforming production lines across the sector:

- Robotic Welding Systems: These systems enhance welding precision and speed while reducing labor costs and improving safety.

- Automated Material Handling: Robotics streamline logistics within fabrication facilities, optimizing workflow and reducing downtime.

5. Artificial Intelligence (AI)

AI technologies are being increasingly adopted to optimize operations:

- Process Optimization: AI can analyze production data to identify inefficiencies and suggest improvements, enhancing overall productivity.

- Predictive Maintenance: By analyzing equipment performance data, AI helps predict maintenance needs before failures occur, thus minimizing downtime.

6. Water Jet Cutting

Water jet cutting technology is gaining popularity due to its versatility:

- Cold Cutting Process: This method uses high-pressure water mixed with abrasives to cut through metals without altering their properties due to heat.

- Precision and Flexibility: It is capable of cutting complex shapes and various materials, making it ideal for diverse applications.

7. Building Information Modeling (BIM)

BIM is revolutionizing project planning and execution in metal fabrication:

- Enhanced Collaboration: BIM allows better coordination among stakeholders by providing a comprehensive digital representation of physical and functional characteristics of projects.

- Improved Efficiency: It facilitates precise planning that leads to reduced waste and improved project timelines.

8. Sustainable Manufacturing Technologies

With an increasing focus on sustainability, many companies are adopting green technologies:

- Energy-Efficient Machinery: Investments in energy-efficient equipment reduce operational costs and environmental impact.

- Recycling Practices: Incorporating recycled materials into production processes not only minimizes waste but also meets growing regulatory demands for sustainability.

The technological advancements in metal fabrication are significantly shaping the industry landscape in Saudi Arabia. From CNC machining and laser cutting to AI integration and sustainable practices, these innovations are enhancing productivity, precision, and competitiveness within the sector.

As Saudi Arabia continues its journey towards economic diversification under Vision 2030, embracing these technologies will be crucial for meeting both domestic demands and global market challenges.