FRP / GRP Handrails by Al Auz Contracting Co

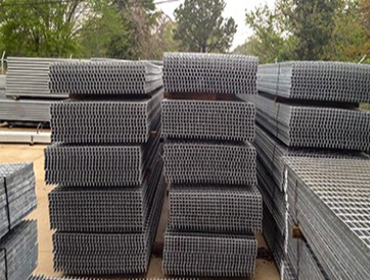

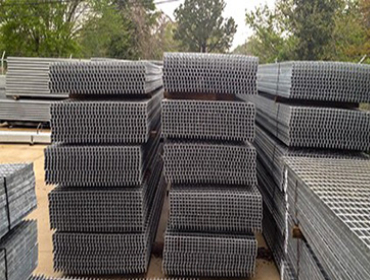

Electro forged grating is produced by placing a series of vertical metal bars at equal distances apart, joined by cross members. Through a process that applies a high current (2500 KVA) along with very high hydraulic pressure, the bars are forge welded together in a rectangular pattern. These gratings are typically made from mild carbon steel and can be supplied with a hot dip galvanized finish for enhanced durability and corrosion resistance.

- Panel Sizes: Standard panels are available in 1000x6000mm or 905x6000mm, with banded or unbanded edges.

- Finish: Offered in self-color or hot dip galvanized finishes for long-term durability.

Electro Forged Steel Gratings:

Standard Panel Specifications:

- Load Bar Depths: Common depths include 25, 30, 32, 35, 38, 40, 45, 50, 60mm, with the ability to produce up to 100mm.

- Load Bar Thickness: Available in 3mm, 4mm, 5mm, 6mm, and 8mm.

- Cross Bar Size: Twisted square bar options of 6mm, 8mm, or 10mm.

- Pitches: 30×100, 41×100, 30×50, 41×50, 34×38.

- Load Bar Type: Available in both plain and serrated styles.

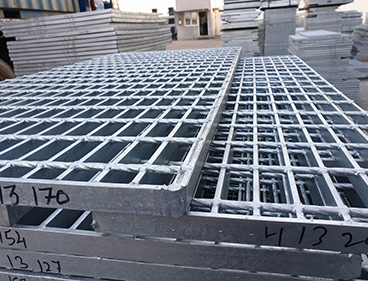

Fabricated Shaped Gratings:

Al Auz Contracting Co offers custom solutions to meet specific project needs. The grating panels are fabricated and customized exactly as per the client’s drawings and requirements. Toe plates, kick plates, and nosing can be welded to the gratings as specified.

Applications:

Fabricated Electro-Forged Gratings are precisely crafted to meet NAAMM standards and can be customized for various applications, including trench gratings with specific angle frames.

Al Auz Contracting Co’s electro forged gratings provide robust and durable solutions, offering excellent load-bearing capacity and resistance to corrosion in challenging environments.