Industrial fabrication plays a crucial role in the economic landscape of the United Arab Emirates (UAE). As a rapidly developing nation, the UAE has established itself as a hub for various industries, including construction, oil and gas, and manufacturing.

In this blog article, we will explore about into the intricacies of industrial fabrication in the UAE, examining its significance, processes, key players, and future trends.

Understanding Industrial Fabrication

Industrial fabrication refers to the process of constructing products by assembling various components. This process typically involves cutting, shaping, and joining materials such as metals, plastics, and composites to create finished products or structures. In the UAE, industrial fabrication encompasses a wide range of activities, including:

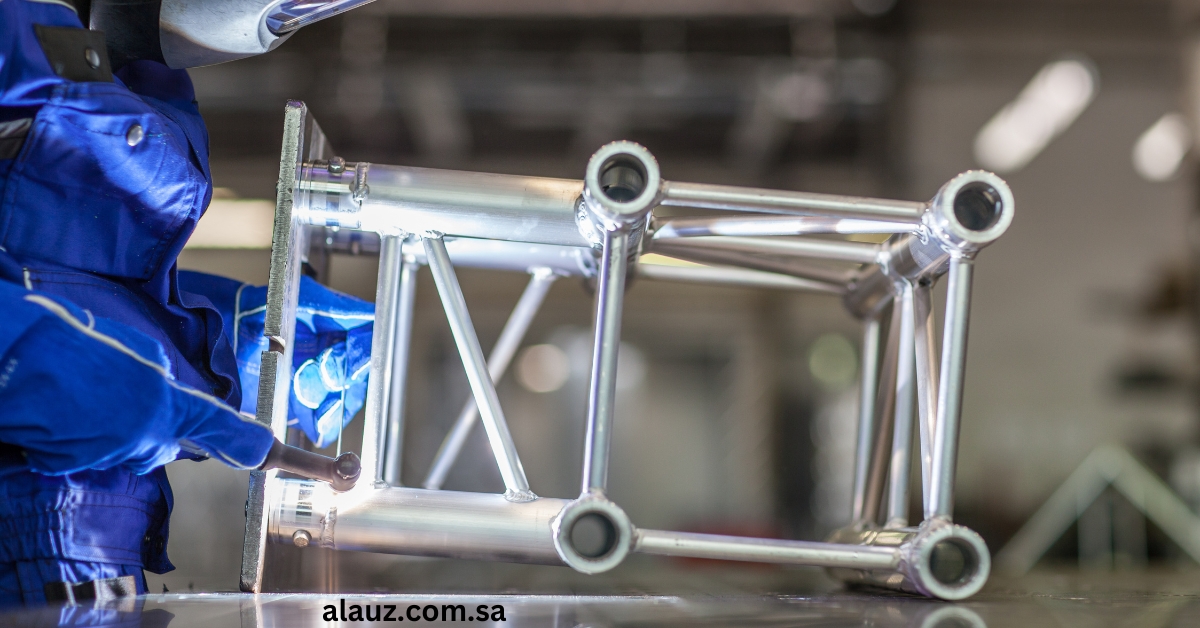

- Steel Fabrication: The process of creating steel structures by cutting, bending, and assembling steel components.

- Metal Fabrication: Involves working with various metals to produce parts and assemblies for different industries.

- Custom Fabrication: Tailored solutions to meet specific client requirements across various sectors.

Importance of Industrial Fabrication in the UAE

The significance of industrial fabrication in the UAE can be attributed to several factors:

- Economic Diversification: As part of its Vision 2021 strategy, the UAE aims to reduce its reliance on oil revenues by diversifying its economy. Industrial fabrication supports this goal by fostering growth in manufacturing and construction sectors.

- Infrastructure Development: The UAE has invested heavily in infrastructure projects such as roads, bridges, and buildings. Industrial fabrication is essential for producing structural components required for these projects.

- Job Creation: The fabrication industry provides numerous job opportunities for skilled laborers and engineers, contributing to the overall employment rate in the country.

Key Industries Utilizing Fabrication Services

Various industries in the UAE rely on industrial fabrication services. Some of the most prominent include:

- Construction: The construction sector is one of the largest consumers of fabricated materials. Steel beams, columns, and other structural components are crucial for building projects.

- Oil and Gas: This sector requires specialized equipment and components that are often fabricated to meet stringent safety and performance standards.

- Manufacturing: From automotive parts to consumer goods, manufacturing relies on precise fabrication techniques to produce high-quality products.

- Renewable Energy: With a growing focus on sustainability, the renewable energy sector is increasingly utilizing fabricated components for solar panels and wind turbines.

Major Players in the UAE Fabrication Industry

The UAE boasts several leading companies specializing in industrial fabrication. Here are some notable players:

1. Assent Steel Industries

Assent Steel Industries is a premier steel fabrication company based in Dubai. They provide comprehensive steel solutions across various sectors. Their services include:

- Design and procurement

- Steel cutting and welding

- Surface treatments

With one of the largest facilities in Dubai covering over 220,000 square meters, Assent Steel can produce up to 120,000 tons of steel annually.

2. Automech Steel

Automech Steel is recognized for its technical capabilities in steel structure manufacturing. They cater to core industries such as oil and gas and power plants. Their expertise includes:

- Design and detailing

- Assembly and installation

- Compliance with quality standards

Automech Steel emphasizes a safe work culture while delivering high-quality products.

3. Prestige Engineering Industries

Established in 1997, Prestige Engineering is a leading player in steel manufacturing and structural engineering. They have extensive facilities equipped with modern machinery for profiling, blasting, and painting. Their notable projects include significant infrastructure developments like the Burj Khalifa support brackets.

The Fabrication Process

The industrial fabrication process typically involves several stages:

- Design: Initial design concepts are developed using Computer-Aided Design (CAD) software to create detailed blueprints.

- Material Selection: Choosing appropriate materials based on project requirements (e.g., strength, weight).

- cutting: Materials are cut to size using various techniques such as laser cutting or plasma cutting.

- Shaping: Bending or forming materials into desired shapes using presses or rollers.

- Assembly: Components are joined together using welding or fastening techniques.

- Finishing: Surface treatments like painting or coating are applied to enhance durability and aesthetics.

Challenges Facing the Fabrication Industry

While industrial fabrication presents numerous opportunities in the UAE, it also faces several challenges:

- Skilled Labor Shortages: There is a growing demand for skilled workers in the fabrication industry; however, shortages can hinder production capabilities.

- Market Competition: Intense competition among fabricators can lead to pricing pressures and reduced profit margins.

- Technological Advancements: The need for continuous investment in modern machinery and technology is essential to remain competitive but can be financially burdensome.

Future Trends in Industrial Fabrication

The future of industrial fabrication in the UAE looks promising due to several emerging trends:

- Automation and Robotics: The integration of automation technologies can enhance efficiency and precision in fabrication processes.

- Sustainability Practices: There is an increasing emphasis on sustainable practices within the industry, including recycling materials and reducing waste.

- Digital Fabrication Techniques: Technologies such as 3D printing are gaining traction for producing complex components with reduced lead times.

Industrial fabrication is an integral part of the UAE’s economic framework, supporting various sectors from construction to renewable energy. As the industry continues to evolve with technological advancements and market demands, it remains essential for businesses to adapt and innovate.

The collaboration between skilled laborers, advanced machinery, and strategic planning will ensure that industrial fabrication not only meets current needs but also paves the way for future growth within this dynamic landscape.

What are the key industries driving the demand for industrial fabrication in the UAE?

Industrial fabrication is a critical component of the UAE’s economic landscape, supporting various sectors that are essential for the country’s growth and diversification.

The demand for industrial fabrication services is driven by several key industries, each contributing significantly to the overall economic framework. Beow we will explore these industries in detail, highlighting their roles and the specific demands they place on industrial fabrication.

1. Construction Industry

The construction sector is one of the largest consumers of industrial fabrication services in the UAE. With ongoing infrastructure projects and urban development initiatives, the demand for fabricated materials continues to rise.

- Infrastructure Development: Major projects such as roads, bridges, and public transportation systems require extensive use of fabricated steel and other materials.

- Residential and Commercial Construction: The growing population and urbanization have led to an increase in residential and commercial buildings, necessitating customized fabrication solutions.

- Government Initiatives: Programs like UAE Vision 2030 aim to enhance infrastructure, further boosting demand for fabrication services.

2. Oil and Gas Sector

The oil and gas industry remains a cornerstone of the UAE economy, driving substantial demand for industrial fabrication.

- Equipment Manufacturing: Fabrication is essential for producing specialized equipment used in exploration, extraction, and refining processes.

- Safety Standards: The industry requires high precision and quality in fabricated components to meet stringent safety regulations.

- Investment in Technology: Continuous investments in advanced technologies for oil extraction and processing increase the need for innovative fabrication solutions.

3. Manufacturing Industry

The manufacturing sector encompasses a wide range of sub-industries that rely heavily on industrial fabrication.

- Automotive Manufacturing: With rising vehicle sales and a focus on local production, the automotive industry requires precise metal fabrication for components.

- Electronics and Appliances: The growing demand for consumer electronics drives the need for fabricated parts in assembly lines.

- Food and Beverage Production: Fabrication services are vital for creating machinery used in food processing and packaging.

4. Aerospace and Defense

The aerospace and defense sectors are emerging as significant drivers of demand for industrial fabrication in the UAE.

- Precision Engineering: These industries require high precision components that can only be produced through advanced fabrication techniques.

- Government Contracts: Increased government spending on defense capabilities has led to more contracts requiring specialized fabrication services.

- Technological Advancements: The integration of new technologies, such as lightweight materials and advanced composites, necessitates innovative fabrication approaches.

5. Renewable Energy Sector

As the UAE shifts towards sustainability, the renewable energy sector is gaining momentum, further driving demand for industrial fabrication.

- Solar Energy Projects: The construction of solar farms requires substantial amounts of fabricated materials for mounting structures and electrical components.

- Wind Energy Development: Fabrication is crucial for producing components used in wind turbines, including towers and blades.

- Government Support: Initiatives aimed at increasing renewable energy capacity create opportunities for fabricators specializing in sustainable technologies.

6. Logistics and Warehousing

The logistics sector is experiencing rapid growth due to increased trade activities and e-commerce demands, which also impacts industrial fabrication needs.

- Warehouse Construction: The development of new logistics facilities requires significant amounts of fabricated steel structures.

- Material Handling Equipment: Fabrication is essential for producing equipment such as shelving systems, conveyors, and loading docks used in warehouses.

Summary Table of Key Industries Driving Demand

| Industry | Key Drivers | Demand Characteristics |

|---|---|---|

| Construction | Infrastructure projects, urbanization | High volume of steel structures |

| Oil and Gas | Equipment manufacturing, safety standards | Precision components for machinery |

| Manufacturing | Automotive, electronics, food production | Customized parts for assembly |

| Aerospace & Defense | Government contracts, precision engineering | High precision components |

| Renewable Energy | Solar/wind projects, government support | Specialized materials for energy systems |

| Logistics | E-commerce growth, warehouse development | Fabricated structures & material handling equipment |

The demand for industrial fabrication in the UAE is primarily driven by key industries such as construction, oil and gas, manufacturing, aerospace and defense, renewable energy, and logistics. Each sector presents unique challenges and opportunities that shape the fabricating landscape.

As these industries continue to evolve with technological advancements and government initiatives aimed at economic diversification, the role of industrial fabrication will remain pivotal in supporting the UAE’s growth trajectory.

How is the UAE’s defense and aerospace sector influencing the metal fabrication market?

The defense and aerospace sector in the United Arab Emirates (UAE) is significantly influencing the metal fabrication market. This influence is manifested through increased demand for advanced fabrication techniques, the development of high-precision components, and government initiatives aimed at enhancing local capabilities. Below are key aspects of how this sector impacts metal fabrication in the UAE.

1. Growing Demand for Precision Fabrication

The defense and aerospace industries require high-precision components that meet stringent safety and performance standards. This demand drives several trends in the metal fabrication market:

- Advanced Manufacturing Techniques: The need for intricate designs and complex geometries in aerospace components has led to an increased adoption of advanced manufacturing techniques, such as laser cutting and additive manufacturing (3D printing). These technologies allow for the production of lightweight yet strong parts essential for aircraft and defense equipment.

- Quality Standards: The rigorous quality standards in these sectors necessitate precision fabrication processes that ensure reliability and safety. As a result, metal fabricators are investing in state-of-the-art equipment to meet these demands.

2. Government Initiatives and Investments

The UAE government is actively promoting the growth of its defense and aerospace sectors as part of its broader economic diversification strategy, particularly under initiatives like UAE Vision 2030. This includes:

- Investment in Local Capabilities: The government encourages local production of defense materials and components, which boosts demand for domestic metal fabrication services. For instance, contracts awarded to local companies for military equipment manufacturing have increased significantly.

- Research and Development Funding: Substantial investments in R&D by the government are aimed at developing advanced technologies for defense applications, thereby creating opportunities for metal fabricators to innovate and expand their offerings.

3. Strategic Partnerships and Collaborations

The UAE’s defense sector has formed strategic partnerships with global aerospace firms to enhance local capabilities. These collaborations often lead to:

- Technology Transfer: Partnerships with international companies facilitate technology transfer, enabling local fabricators to adopt advanced manufacturing techniques and improve their production processes.

- Joint Ventures: Joint ventures between local firms and international players often focus on producing specific defense-related products, increasing the demand for specialized metal fabrication services tailored to these products.

4. Expanding Market Opportunities

The growth of the defense and aerospace sectors is opening new market opportunities for metal fabricators:

- Increased Production Requirements: As the UAE expands its defense capabilities, there is a growing need for various military equipment, including armored vehicles, drones, and munitions. Each of these requires extensive metal fabrication services.

- Emerging Technologies: The rise of new technologies such as unmanned aerial vehicles (UAVs) necessitates specialized fabrication processes that can accommodate unique material properties and design specifications.

5. Economic Diversification Efforts

The UAE’s focus on diversifying its economy away from oil dependency has led to a greater emphasis on developing its industrial base, particularly in sectors like aerospace and defense:

- Local Manufacturing Growth: By fostering a robust local manufacturing environment, including metal fabrication, the UAE aims to enhance its self-sufficiency in critical sectors while creating jobs and stimulating economic growth.

- Sustainability Goals: The integration of sustainability practices within the defense sector also influences metal fabrication. For example, initiatives aimed at reducing carbon emissions require fabricators to adopt greener practices in their operations.

Summary Table of Influences on Metal Fabrication Market

| Influence Factor | Description |

|---|---|

| Growing Demand for Precision | Increased need for high-quality, precise components drives advanced techniques. |

| Government Initiatives | Investments in local capabilities enhance demand for domestic fabrication services. |

| Strategic Partnerships | Collaborations with global firms lead to technology transfer and innovation. |

| Expanding Market Opportunities | Growth in military equipment production increases demand for specialized services. |

| Economic Diversification Efforts | Focus on local manufacturing stimulates job creation and economic growth. |

The defense and aerospace sector is a significant driver of growth in the UAE’s metal fabrication market. Through increased demand for precision components, government support for local manufacturing, strategic partnerships with global players, expanding market opportunities, and efforts towards economic diversification, this sector is shaping the future landscape of metal fabrication in the UAE.

As these industries continue to evolve, they will likely present further opportunities for innovation and expansion within the metal fabrication market.